One Step Surface Transformation

Remove the Oxide Layer

The oxide layer presents a barrier to coating adhesion that must be removed prior to the application of high performance coatings.

Roughen the Metal Surface

Roughening the substrate and exposing unreacted metal provides an ideal surface for exceptional coating adhesion.

Apply Unique Skins

CoBlast Skins are highly integrated with the substrate. This gives them excellent durability and stability, and allows previously impossible properties to be achieved.

In One Step

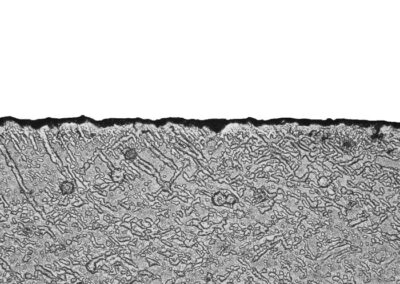

CoBlast is a one-step, ambient temperature, ambient pressure process that uses conventional grit/micro-blasting equipment to remove a metal’s natural oxide layer and replace it with a desired functional Skin. Abrasive and coating powders are simultaneously blasted onto the metal surface from a single nozzle. The abrasive mechanically abrades the substrate, exposing active chemical bond to which the coating particles bond before an oxide layer can reform. The inert nature of the abrasive ensures that it does not easily form chemical bonds, so that the process forms a coating with excellent coverage, with little or no abrasive remaining on the surface or embedded in the substrate. The level of coating/substrate integration achieved by this process is far beyond most coating methods and leads to some unique capabilities.

The Coating

Coating Properties

Clean, Durable, Stable, Thin, Flexible

CoBlast is solvent free, making the resulting coating clean, durable, and stable. Inorganic coatings can be applied in this manner to provide exceptional high temperature performance and wear resistance. CoBlast skins are typically 2-5 microns in thickness, giving them excellent flexibility and resistance to delamination.

Substrate Geometries

Complex 3D shapes, Fine details, Flat plates, Tubes, Foils, Wires, Foams

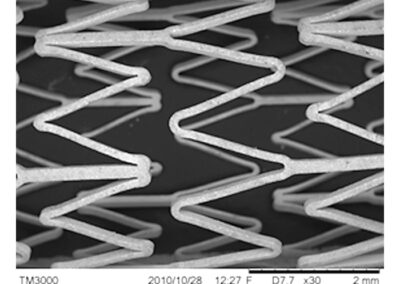

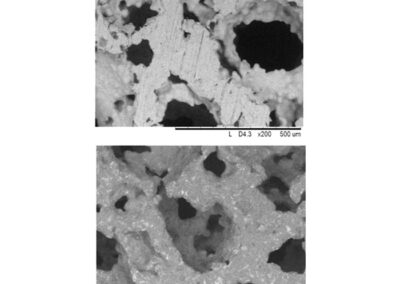

CoBlast Skins can be applied to almost any substrate geometry, as the nozzle is easily mounted on standard industrial robots and other automation equipment. The process is line of sight and allows for convenient masking of uncoated sections. In general, if you can grit-blast or micro-blast it, you can CoBlast it. The low coating thickness means that fine surface details are preserved. The abrasive and coating materials, and the process parameters can be tailored to coat delicate parts without mechanical or thermal damage; Skins have been applied to titanium foils as thin as 25 microns, and to delicate structures including stents and metal foams.

Substrate Materials

Titanium, Stainless Steel, Mild Steel, Aluminium, Magnesium, Nitinol, Copper, Cobalt Chrome, Inconel and more

Standard CoBlast process parameters can be applied to many substrate materials and Enbio can also provide parameters optimised for specific substrates. CoBlast Skins integrate exceptionally well even with substrates that normally suffer poor coating adhesion, thanks to the simultaneous roughening, chemical activation, and coating deposition. CoBlast is an ambient temperature, ambient pressure process that can be applied to sensitive substrates without damage. Heat treated alloys can be coated without destroying the properties achieved during the heat treatment process:

Coated nitinol parts have shown no loss of superelasticity or shape memory.

Titanium can be coated with no evidence of oxygen infiltration or α-case formation.

No heat affected zone is observed after CoBlast.

Complex heat treatments of alloys such as aerospace aluminium grades are preserved.

The range of substrates is constantly expanding to include new materials and new grades, for example: titanium (G2, G5), aluminium (2000 and 6000 series) and stainless steel (304, 316). Please contact us with any queries relating to specific substrates.